The Art of Design, Engineering and Quality Consolidation

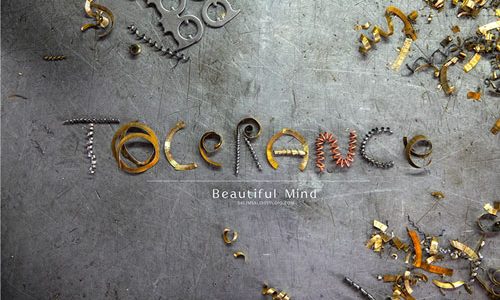

Tolerance | The Art of Design, Engineering and Quality Consolidation

a few words

About Us

Tolerance company was established in 1984 with the help of a group of outstanding engineers and designers in the field of door hardware industry.

In line with the rapid growth of this industry in the world , Tolerance with its group of highly dedicated craftsmen, Continue on About Us …

Tolerance sections

Learn more about our sections

Molding

The company manufactures molds in the process of designing and molding the door according to the final design of the product using the latest Iranian technologies.

Die Casting

Tolerance manufactures its products with the most up-to-date machinery (hot chamber, cold chamber) and the most advanced raw materials (zamac).

Polishing

To obtain a smooth and glossy surface, the steps (polishing and glazing) are performed with great accuracy.

Plating

The purpose of this step is to create a transparent coating layer with different colors on the parts.

All electroplating processes including copper, nickel, worm and so on are carried out using the most up-to-date technologies in the world.

It is very important for this company to reduce the environmental pollution in the factory complex by using the most advanced wastewater treatment systems.

Laser

Engraving the name of the company on the product itself indicates the reliability of the part manufacturing operation. Tolerance Company marks all its products by laser labeling.

assembly

All the products are assembled and packed in the assembly line of Tolerance and fully supervised by the quality control unit, with experienced and trained personnel along with the appropriate equipment and supplies.

PVD

The purpose of this step is to create a transparent coating layer with different colors on the parts.

All electroplating processes including copper, nickel, worm and so on are carried out using the most up-to-date technologies in the world.

PVD

It′s interesting to note that the company has zeroed in on environmental pollution by using the most advanced wastewater treatment systems.